FACTORY

FACTORY

From forging and rolling to processing and inspection, Fujita fulfills customer needs through extensive facilities and collaboration with our suppliers.

Okazaki Production Facilities : Approximately 130 machines , Cold forging machines, Thread tolling machines, Cutting machines, and Heat Treatment furnaces.

In house Products

Fastening Parts

Specialty Parts

FUJITA BRAND

Fujita manufactures various reliable products, ranging from small to mass volume production, including complex products. We ensure high-quality and consistent supply and leverage both automated efficiency and the human touch to deliver reliability that builds formidable brand strength.

The manufacturing capability to fulfill customer trust

Fujita's manufacturing capabilities for fastening parts meet customer needs through the utilization of various rolling machines, trimming processing, and splitting processing machines. Additionally, we possess manufacturing capabilities for specialty parts, boasting high production efficiency. For instance, our multi-stage formers are capable of cold forging processing with a maximum cutting diameter of Φ27 and a length of up to 100mm.

Consistent In-House Heat Treatment Process

Fujita has the ability to conduct a consistent in-house heat treatment process, enhancing the strength of various components we manufacture. With an automated mesh belt continuous quenching and tempering furnace, we can accommodate a variety of parts, including boron steel, alloy steel, and carbon steel.

Specialization in Geomet Coating Process

At the Toyota facility, we have an in-house Geomet coating process. This process is water-based, completely chrome-free, environmentally and operationally friendly, providing high heat resistance and corrosion resistance of over 1500 hours in salt spray tests.

With two dip spin lines machines and one hanger line machine, along with many qualified specialists, we aim to provide customer benefits such as cost reduction.

Exhaustive Quality Assurance

At the core of Fujita's brand strength is quality assurance, which ensures thorough inspections at every single process prior to shipment.

Fujita provides comprehensive quality inspections using shape measuring machines, three-dimensional measuring machines, and image inspection machines tailored to the required quality standards. We have obtained certificates for IATF and ISO quality management systems.

An integrated line that enhances brand power

Fujita achieves a concrete and consistent process line from cutting, cleaning, assembly, to full inspection, enhancing the reduction in work-in-process inventory and enabling high-efficiency production.

Fujita Skilled Teams Lead Manufacturing

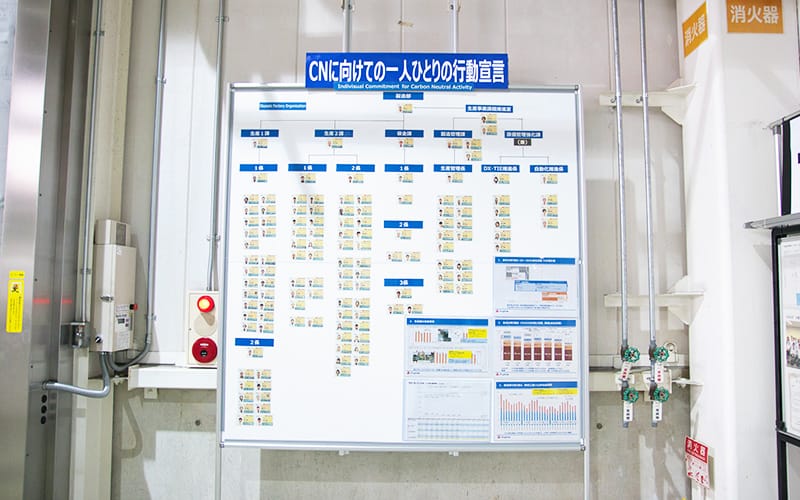

Master of Manufacturing is the motto, and human development is emphasized in manufacturing sites where we prioritize the power of people over automation.

With the slogan "EVERYONE LEADS the ROLE," each individual approaches their daily tasks and improvements with a sense of responsibility and passion, understanding the product purpose and post-distribution usage, and paying attention to the details as a "professional".

THOUGHT

Fujita products are used everywhere in daily life, and in some cases, they are even used in safety-critical applications. Therefore, we manufacture every single product with the highest level of technology and a profound sense of responsibility as we engage in manufacturing.